Press

Press

02-04-2024

Honored with the prestigious 2023 global Supplier Recognition Award by ConocoPhillips!

08-03-2024

Celebrating Women in Tech: Spotlight on Rebecca

23-02-2024

Sheltersuit Foundation Distributes First Batch of Sheltersuits in Toronto, Canada!

06-02-2024

Demo Day at PRCI 2024

25-01-2024

Announcement of Area Director Middle East

05-12-2023

New Inside Intero Episodes Now Streaming!

30-10-2023

Announcement of Customer Delivery and Quality Manager, Americas

07-09-2023

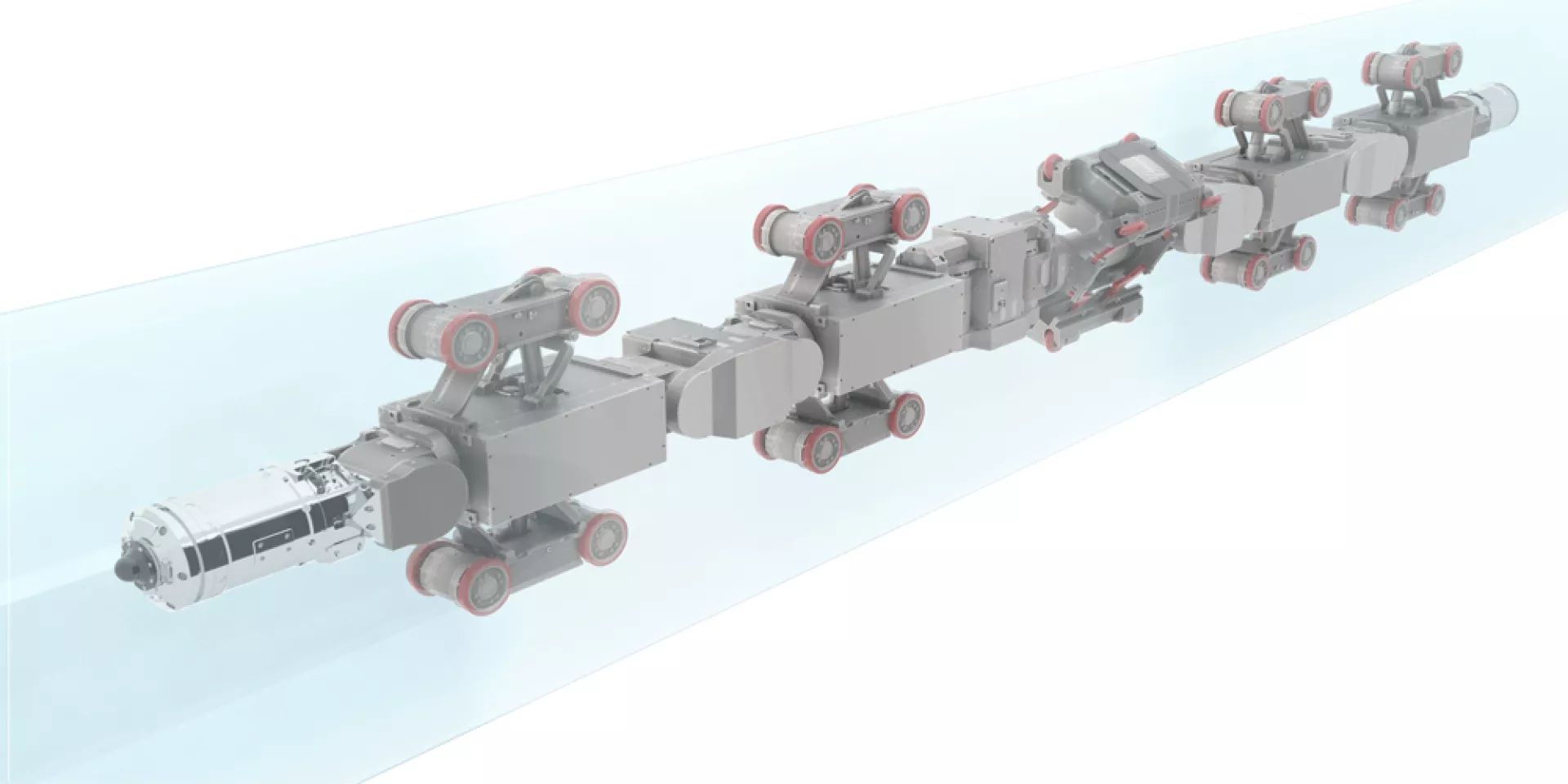

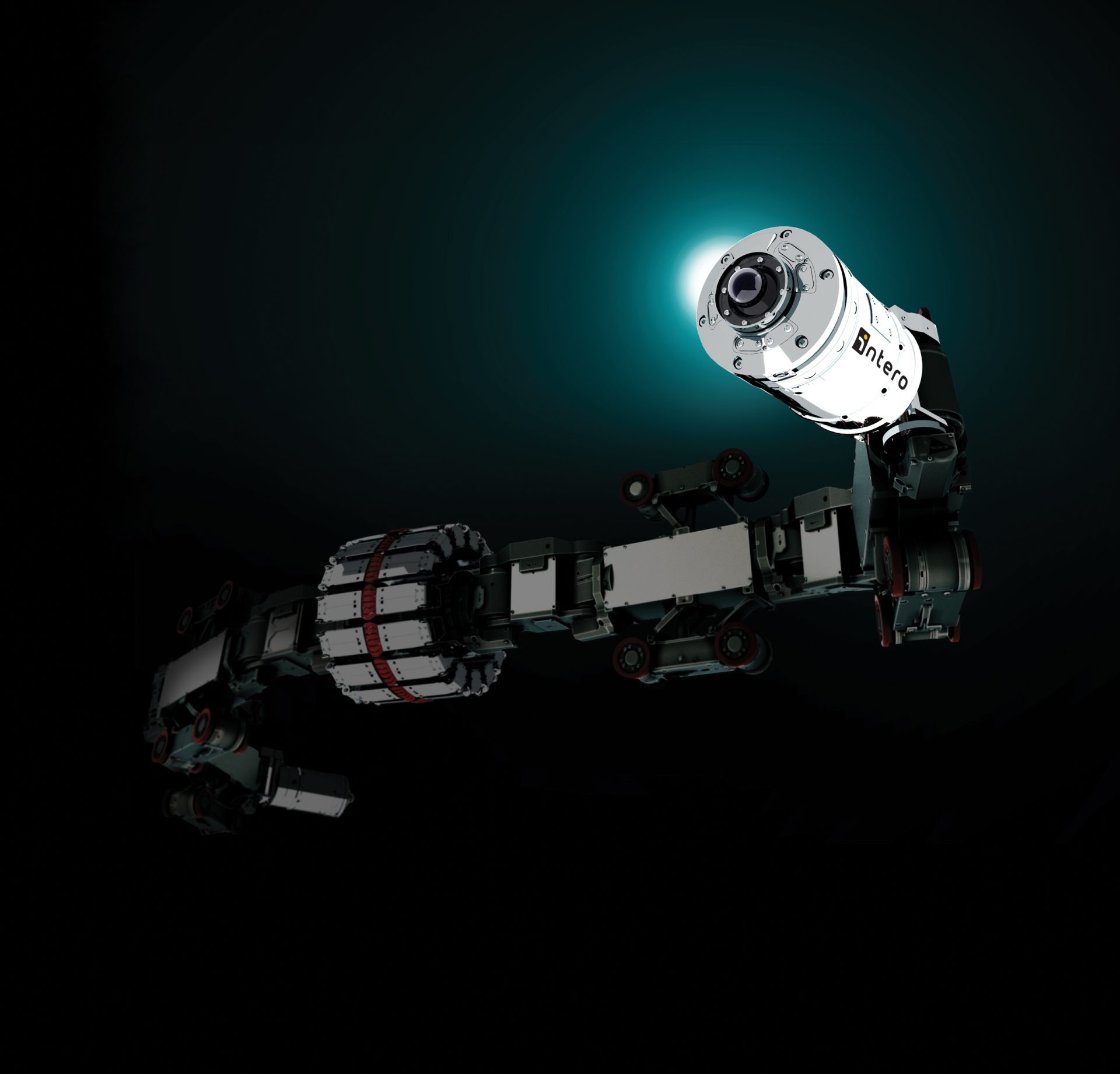

Detection of Cracks in Difficult-to-Inspect Pipelines Now Possible with Robotic Technology

08-08-2023

Announcement of New Director Inspection Services EUR & RoW

11-07-2023

Intero – The Sniffers announces its support for Aiming for Zero Methane Emissions

04-07-2023

A Heartwarming Journey: Making a Difference in Lyon

In early 2023, on a bitterly cold night, we joined forces with the Red Cross and Samusocial de Paris to distribute 60 life-saving Sheltersuits. Thanks to the support of our colleague Barbara and Karem, we aimed to make a significant impact through small acts of kindness.

26-06-2023

Intensive ILI Training in Taiwan

We were asked to facilitate an intensive inline inspection training for 23 trainees of our client

24-03-2023

Refreshing our Intero brand

We are excited to share that Intero moves forward as one strong, global brand!

24-03-2023

Philippe Guldemont appointed as Managing Director of Intero - The Sniffers

Intero-owned company The Sniffers appoints Mr. Philippe Guldemont as Managing Director effective as of June 7th 2022.

24-03-2023

Contract Award The Baltic Pipe Project

We are happy to announce that we have been awarded the Baltic Pipe Project contract!

16-03-2023

Intero – The Sniffers and Sensirion Connected Solutions partner up to tackle methane emissions

Sensirion Connected Solutions and Intero – The Sniffers have partnered up to help enable the oil and gas industry to reduce methane emissions and comply with voluntary initiatives and new standards.

21-02-2023

Advisory towards OGMP2.0

Creating a customized roadmap toward the Gold Standard.

12-09-2022

The road to the OGMP Gold Standard with FGSZ

OGMP member FGSZ shares how they are working towards the OGMP Gold Standard.

12-09-2022

Case study: from Word and Excel to a pipeline integrity management platform

11-03-2022

How to start with Leak Detection And Repair to guarantee future success

16-02-2022

Pipe Explorer compatible with Mueller Fittings

Since last year, our Pipe Explorer is compatible with Mueller bottom-out fittings.

31-01-2022

High Flow Sampling to quantify methane emissions on vents: what, why, and how

05-11-2021

5 success factors to manage the CP system on your pipeline network

25-10-2021

Effective Leak Detection And Repair (LDAR) for Genel Energy in Iraq

11-03-2021

Planning an LDAR campaign? Check these 6 common pitfalls first

Are you planning to start implementing or improving your LDAR program? Check these 6 common pitfalls first.

28-07-2020

Effective cathodic protection, pipeline inspections and third party interferences for BASF

22-06-2020

Why Gasunie exceeds expectations to reach emission targets

12-05-2020

Why Elia relies on sniffing dogs for leak detection on underground cables

08-04-2020

Why LDAR is more than holding a camera for Shell Deutschland

18-02-2020

Helping Romania achieve accurate methane emission figures

We provided our expertise in methane emission management as a partner of Utrecht University during the unique ROMEO project.

06-01-2020

LDAR, vent and flare loss monitoring, and steam loss monitoring for TotalEnergies

23-10-2019